- BaoZhu Str. 8, Economic Development Zone, XianAn District, XianNing City, 437000, Hubei Province, China

Top 5 Advantages of Magnesium Alloy Die Casting for Modern Manufacturing

Top 5 Advantages of Magnesium Alloy Die Casting for Modern Manufacturing

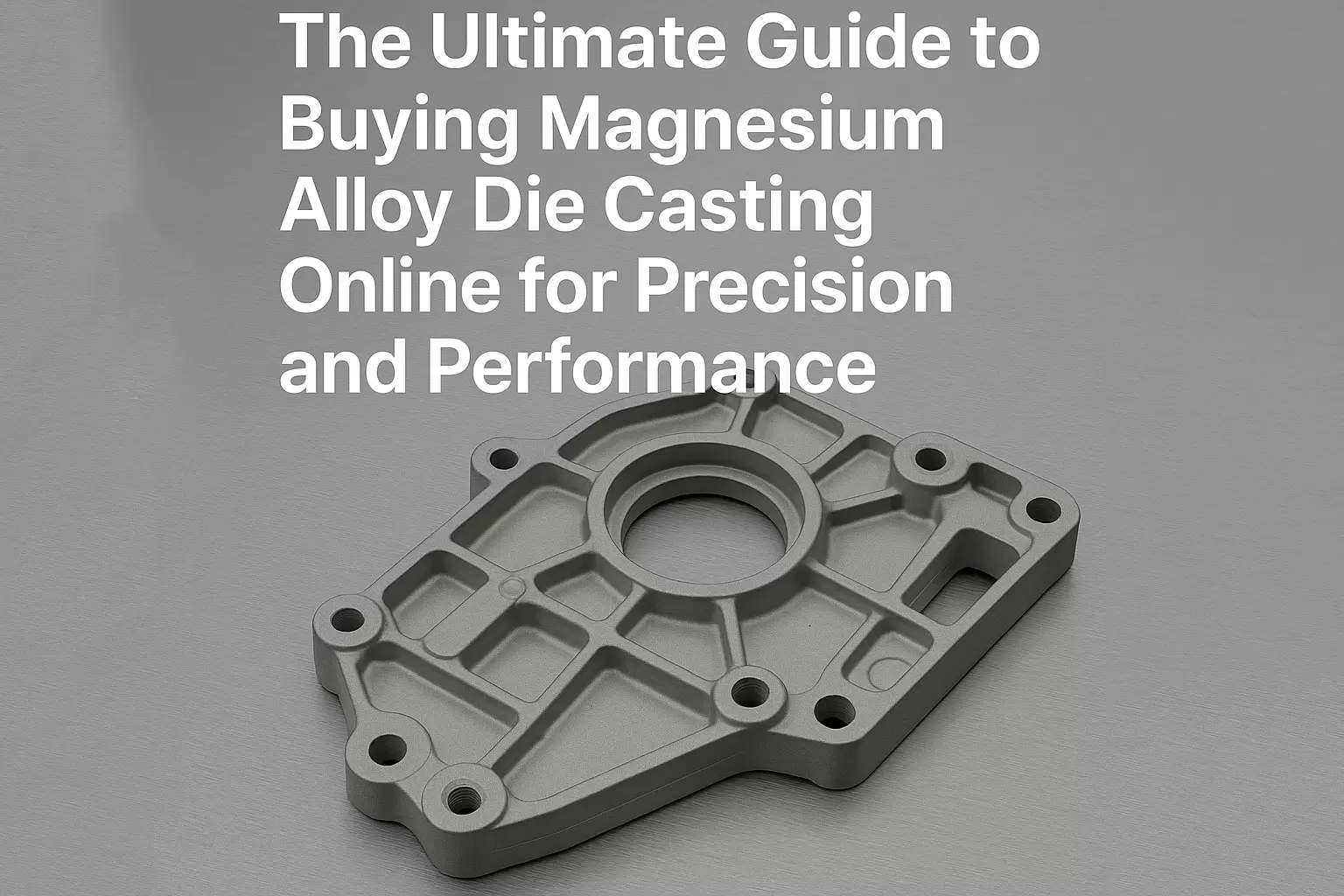

Manufacturing industry of today, which is changing rapidly, companies are continually in a quest for the material that would offer them strength, lightness of the object, and the ability to create flexible designs. A material, whichever it is, that gains the most buzz for the last couple of years is none other than magnesium alloy die casting. Being used to its outstanding performance in a large number of industries like automotive, electronics, aerospace, and medical equipment, magnesium alloy die casting is becoming the first choice of precision components.At xiongzhigroup, we are committed to providing top-notch magnesium alloy products to customers worldwide. If you are looking to buy magnesium alloy die casting online or place an order for magnesium alloy die casting online, knowing its benefits will certainly assist you in making a favorable decision.

1. Lightweight Yet Exceptionally Strong

The single most important feature of a magnesium alloy die casting that comes to mind would probably be its remarkable strength-to-weight ratio. Magnesium is around one-third lighter than aluminum and almost four-times lighter than steel, thus making it one of the lightest structural metals that can be used for industrial purposes.Even magnesium alloys do not weigh much, yet they are good enough to provide high mechanical strength and stiffness. Therefore, these metals become a perfect choice for industries where weight has to be reduced to a certain level without the loss of performance, e.g., automotive parts, consumer electronics housings, and aerospace components. The evolution in fuel consumption is a direct result of the lighter components that are, indeed, more easily handled, and this leads to the production cost going down. If you order magnesium alloy die casting online from xiongzhigroup online, then you will be receiving parts that are durable yet light-weighted efficient.

2. Excellent Dimensional Accuracy and Precision

Magnesium alloy die casting is a process that results in extremely accurate and dimensionally stable parts. The material has excellent flow characteristics which enable it to fill complex molds having thin walls and intricate shapes, thus achieving tight tolerances and uniform quality.Such accuracy eliminates the need for secondary machining that is time-demanding and production-cost increasing. The manufacturers are now able to get a flawless finish, sharp edges, and complex geometries in a single casting process. Companies that require the highest standard of engineering specifications when buying magnesium alloy die casting for sale can be sure that xiongzhigroup will meet their expectations.

3. Superior Thermal and Electrical Conductivity

One of the major advantages magnesium alloys can boast of is their very good thermal conductivity which makes them invaluable to parts that are exposed to heat or electrical loads. For this reason, magnesium alloy die casting has found its way into electronic housings, LED components, power tools, and communication devices industries.By removing generated heat, the safety, the performance, and the life of the product are elevated. Besides, Magnesium is a natural electromagnetic shield and therefore it is preferred material in electronic enclosures that helps to keep the sensitive equipment away from interference. A manufacturer who buymagnesium alloy die casting online will be able to produce devices that are not only thermally efficient but also electrically strong.

4. Cost-Effective for High-Volume Production

It might seem that magnesium alloys are high-end products, but the truth is that magnesium alloy die casting is very economical in large-scale production. The operation is completed very quickly as compared to other metals. The reason behind it is the low melting point of magnesium. The resulting lower consumption of energy leads to the reduction of the manufacturing costs.Furthermore, the feature of being able to generate parts that are almost in their final shape translates to less waste of materials and less money spent on post-processing. Thus, it is possible to say that magnesium alloy die casting is a viable option for volumetric production without quality being compromised. We at xiongzhigroup work toward providing you with a convenient way of placing an order for magnesium alloy die casting online with affordable prices, good supply, and reliable delivery for both small and large production runs.

5. Eco-Friendly and Highly Recyclable

The issue of sustainability has become the primary concern of all the industries, and magnesium alloy die casting is in line with the requirement of environmentally friendly manufacturing. In fact, magnesium is completely recyclable, and the recycled magnesium is as good as the original one, hence suitable for closed-loop production processes.The use of magnesium alloys leads to less materials being used overall due to the light design of the product, and it also results in the lowering of emissions from transportation. Therefore, the companies that will be using this material to lessen their environmental impact while still meeting the high-performance standards will be making a wise decision. When you choose the option of buying magnesium alloy die casting for sale at xiongzhigroup, you will be going for a sustainable manufacturing practice.

Conclusion

The combination of lightness and strength, accuracy, heat management capability, cost-efficiency, and eco-friendliness is what makes magnesium alloy die casting such a powerful tool to have in the arsenal of a modern manufacturer who has to deal with a variety of industries. In a nutshell, if you are in need of dependable magnesium alloy die casting suppliers, then xiongzhigroup would be a perfect fit for your business. Discover our services today and get the benefits of an advanced magnesium alloy die casting tailored to your business needs.

XiongZhiGroup Co., Ltd

XiongZhiGroup Co., Ltd